At ZHEJIANG Dryta TECHNOLOGY CO., LTD, our factory is more than just a production site – it is the heart of our research, development, and innovation. Equipped with advanced manufacturing facilities and stringent quality control systems, we ensure that every public restroom product we produce meets the highest international standards.

Our high-precision injection molding equipment ensures that components for hand dryers, soap dispensers, paper towel dispensers, and baby changing stations are formed with exceptional accuracy and smooth finishes, meeting diverse design requirements.

Our semi-automated assembly lines combine mechanical efficiency with skilled manual assembly, ensuring flexibility for customized requirements. This approach allows us to maintain high production efficiency while leveraging human expertise to guarantee the quality and consistency of each product batch.

With advanced laser cutting and sheet metal processing equipment, we can customize stainless steel parts with precision and flexibility, widely applied in the manufacturing of high-end soap dispensers, paper towel dispensers, and hand dryer housings.

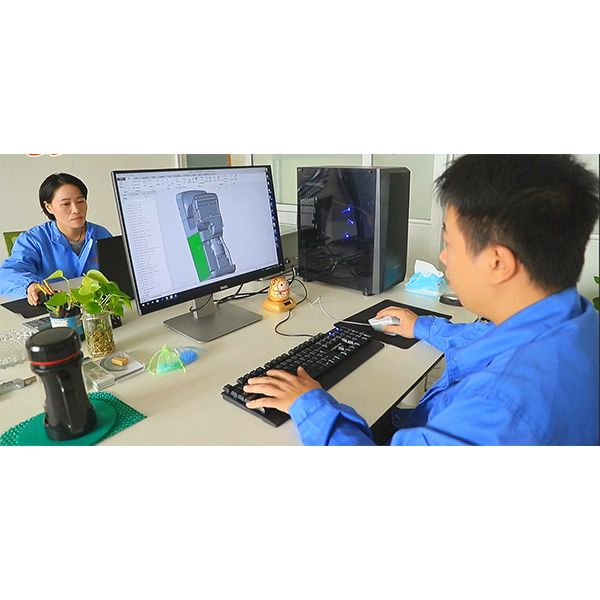

Our R&D team integrates innovative thinking with precision manufacturing to continuously upgrade public hygiene products.

From exterior styling to internal structures, our engineers and designers work closely to transform creative ideas into functional prototypes in a short time, supported by rapid prototyping equipment. These prototypes undergo thorough evaluation to ensure both aesthetics and performance.

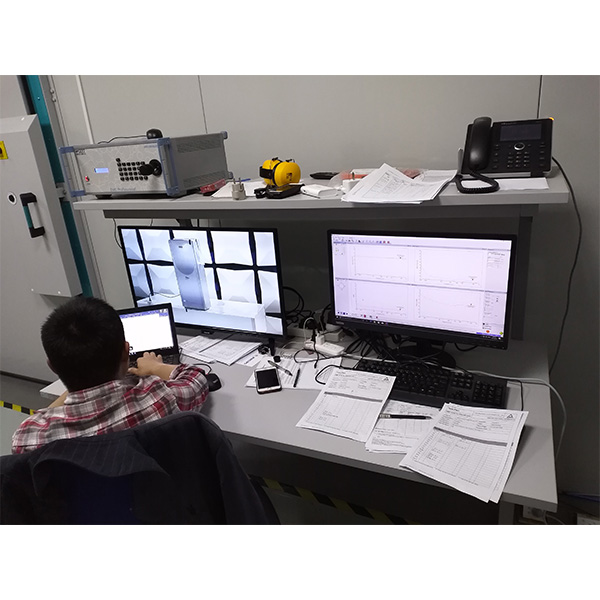

Every product goes through rigorous performance and durability testing, including waterproof, dustproof, impact resistance, and safety evaluations, ensuring reliability even under heavy public usage.

Helen@dryta.com

Helen@dryta.com

+8618657679988

+8618657679988 0086-574-62759992

0086-574-62759992 No. 8, Jinfeng Road, Yuyao, Ningbo, Zhejiang,China.

No. 8, Jinfeng Road, Yuyao, Ningbo, Zhejiang,China.Copyright © 2025 DRYTA All Right Reserved. Designed & SEO by followala.cn Sitemap | XML